Dear Lighting Designers, Engineers, and Procurement Managers,

Do you often face these frustrations?

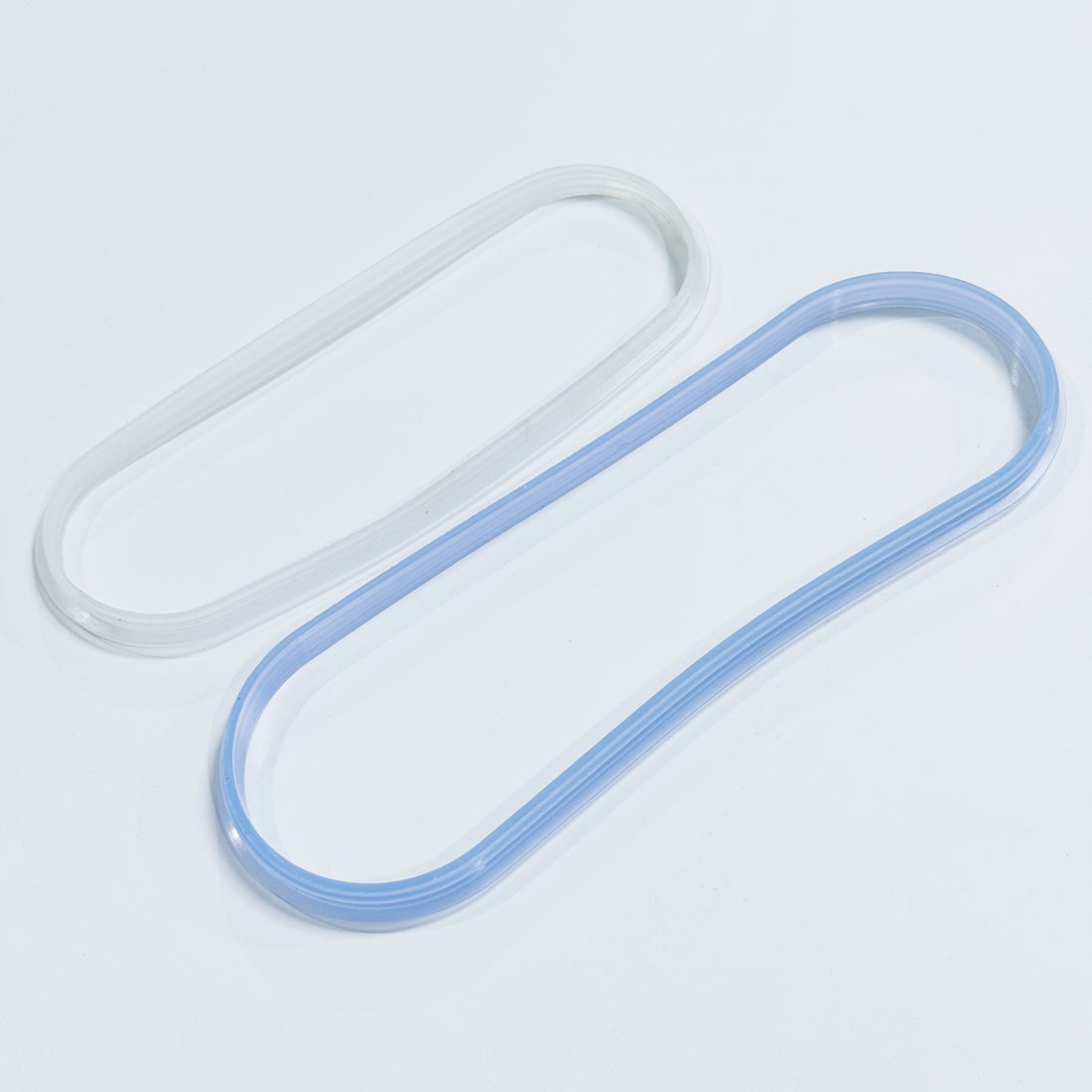

An innovative lighting design you've poured your heart into gets stuck because of a non-standard, irregularly-shaped sealing or insulating component?

After scouring the market, the parts you find either have slight dimensional variances or fail to meet performance specs, forcing you to compromise your original design vision?

The mold cost for a low-volume but critical small part is prohibitively expensive, making it seem unfeasible?

If any of these points resonate with you, please read on. The problems you're facing are exactly what we have specialized in solving for the past 14 years.

We are a silicone rubber product factory based in Jiangmen, Guangdong. Our core value is providing you with: high-precision, low-volume, custom-shaped silicone component services based on your drawings or samples.

We Understand Your Challenges

Innovation in the lighting industry moves fast. Streamlined aesthetics, integrated structures, unique thermal designs... these highlights often come with highly complex internal layouts. That seemingly insignificant silicone part often becomes the crucial element for:

Safety (Insulation, Flame Retardancy)

Quality (Precise Sealing, Vibration Damping & Noise Reduction)

Assembly Efficiency (Perfect Fit, Streamlining Production)

Settling for an ill-fitting component means building potential issues into your final product.

Our Solution: Hand Us the Challenge, We'll Deliver Precision

We believe the best component is one 'born' from the design itself. You shouldn't have to compromise excellent designs due to supply chain limitations.

1. Powerful Customization Capability, Guarding Your Creativity

Simply provide us with drawings or a sample. Regardless of whether your silicone part requires:

Complex Shapes (Irregular, 3D Curves, Ultra-thin/Thick)

Intricate Structures (Multi-aperture, Multi-layer, Embedded Framework)

Stringent Requirements (Tight Tolerances, Specific Hardness, Food-Grade/Flame-Retardant Materials)

Our professional drawing review, precision mold manufacturing, and mature curing process can achieve perfect replication – what you see (in design) is what you get.

2. Flexible Low-Volume Cooperation, Reducing Innovation Pressure

We fully understand the needs during new product development. Don't worry about high Minimum Order Quantities (MOQs). We support low-volume pilot production, helping you verify designs and launch to market with lower upfront costs.

3. An "Expert-Level" Collaborative Experience, Beyond Manufacturing

Choosing us means gaining not just a supplier, but an R&D partner. Our engineering team provides professional advice on material selection, structural optimization, and production feasibility, working with you to find the optimal solution.